– The material contact part is made of 304 stainless steel, the rest is carbon steel;

– Rod pin made of wear-resistant alloy steel;

– The two needle discs in the mill rotate at high speed in opposite directions;

– The fineness of the product is achieved by adjusting the speed of the dial;

– The machine is easy to clean, just open the grinding door;

– No sieve, smooth discharge, high capacity and low operation cost; dual power can be used to achieve a linear speed above 200m/s to obtain greater crushing power.

Pin Mill

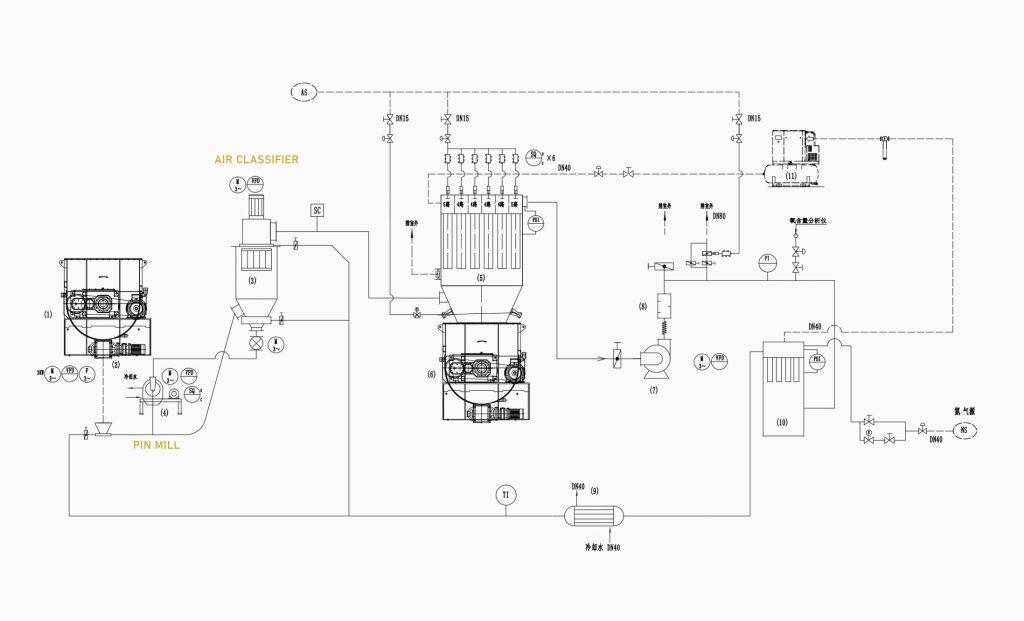

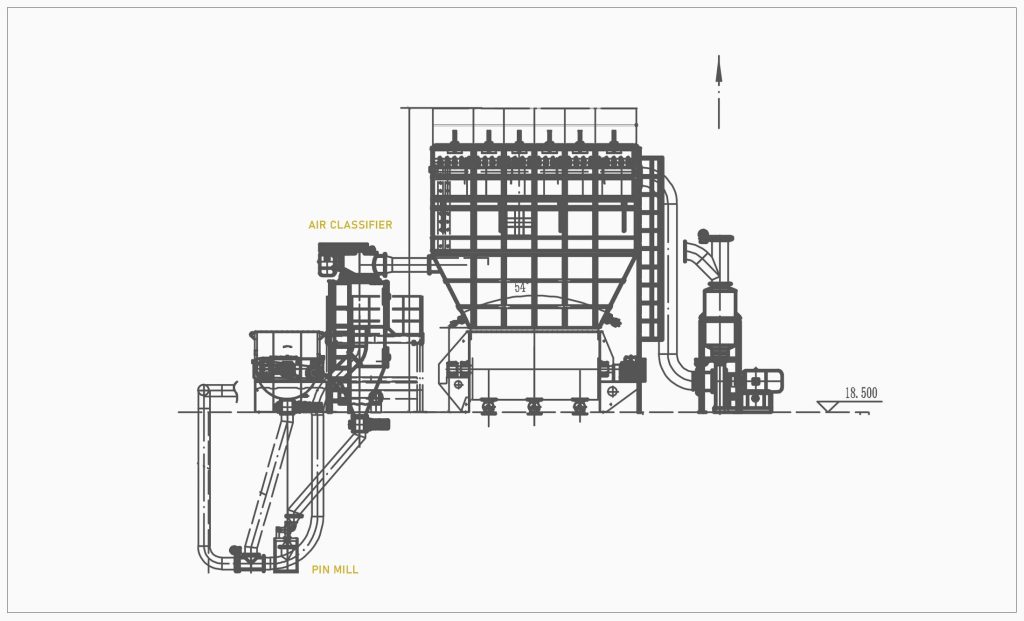

Pin Mill for Sulfur Working Principle

Sulfur powder are uniformly fed into the grinding chamber by the feeding system, and are strongly impacted by the high-speed rotating grinding movable disk. At the same time, they are subjected to various comprehensive forces such as friction, shearing, and collision between the static disk and the gear ring, so that the sulfur powder are crushed. The grinding movable disk and the static disk can be combined with different structures to meet the different crushing needs.

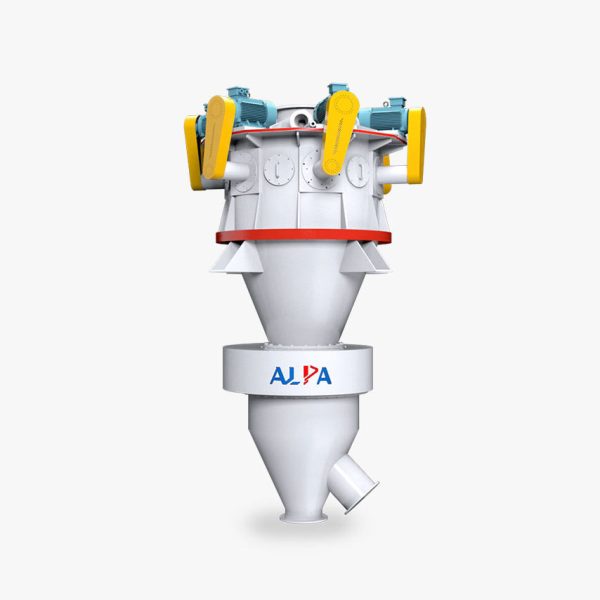

Air Classifier

Realize the separation of particles of different sizes

According to the centrifugal force, gravity, inertial force, etc. of particles of different sizes in the medium (usually air), different trajectories are generated, so as to realize the separation of particles of different sizes.

- Secondary washing air flow will be free to inhale, accelerate material dispersion.

- Grinding is in closed system, little dust, low noise in a clean and environmentally friendly process.

- The main engine and impeller are made of 304 stainless steel, in line with GMP, C-GMP, FDA certification requirements.

- Optional explosion-proof design, can also be upgraded to a nitrogen circulation system.

Air Classifier for Sulfur Working Principle

Under the action of the fan, sulfur powder moves to the classification area at a high speed from the lower inlet of the classifier with the updraft. Under the action of the strong centrifugal force generated by the high-speed rotating classification turbine, sulfur powder is separated, and the fine particles meeting the particle size requirements enter the cyclone separator or dust collector through the blade gap of the classification wheel for collection. The velocity of some fine particles entrained by coarse particles disappears after hitting the wall, and then decreases to the secondary air outlet along the wall of the cylinder. Through the strong washing effect of the secondary air, the coarse and fine particles are separated, the fine particles rise to the secondary classification in the classification area, and the coarse particles drop to the discharge port for discharge.