Sulfur is mainly used to produce sulfuric acid, dyes, fireworks and rubber products, and can also be used in military industry, medicine, pesticides and other departments. Food sulphur can be used in the food industry for antiseptic, insecticide, bleaching, fumigation, etc. It can also be used in the starch industry to soften corn and other raw materials. The sulfur powder produced by this process is especially suitable for fireworks, military and pharmaceutical industries, as well as for bleaching and dyeing purposes.

Industrial sulfur is toxic and flammable, with a spontaneous combustion temperature of 205°C. Sulphur dust is explosive. The generation or release of sulphur dust should be prevented when using and transporting sulphur powder. The production, storage, transportation and use of liquid sulfur shall comply with relevant safety regulations. Open flames are strictly prohibited. Burning sulphur is allowed to be extinguished by water spray etc. Staff engaged in the production, transportation, storage and processing of sulfur powder should use certain protective equipment during operation.

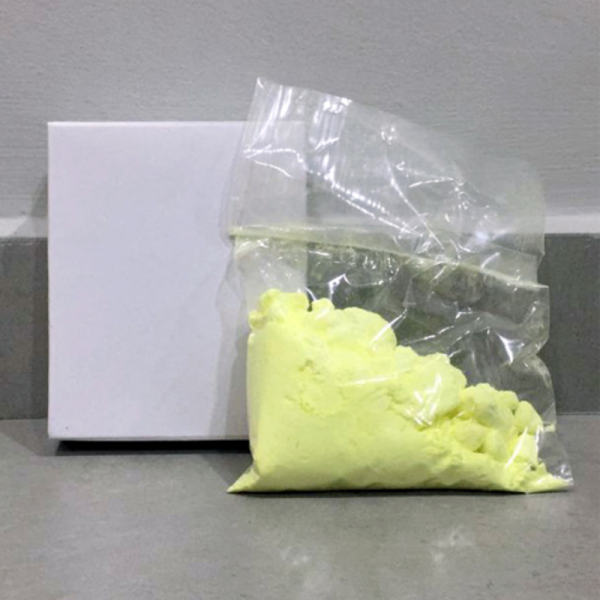

The packaging container of sulphur powder should have obvious and firm signs, including: manufacturer’s name, factory address, product name, trademark, grade, net mass, batch number, production date, this standard number and “flammable solids” that meet the regulations logo. Solid sulfur flakes can be packaged in plastic woven bags or bags lined with plastic film, or in bulk. The bulk sulfur can be packaged without plastic film bags. Bulk products should be covered, but powdered sulfur should not be packaged in bulk.