ALPA Powder Technology

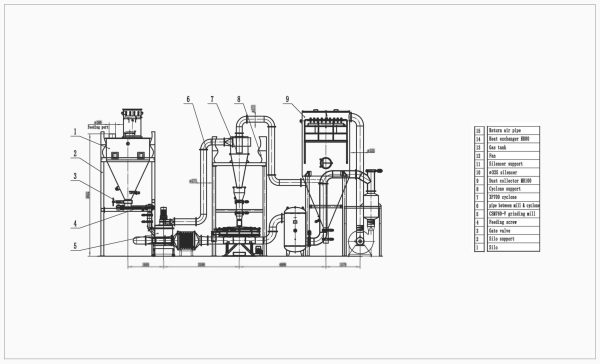

Process Flow Solution I

This scheme adopts the integrated design of grinding and classifying

The material enters the grinder through the quantitative feeding system, the grinded sulfur powder enters the classifying area, the qualified products are collected and packed, the coarse powder returns to the grinder area for further grinding, completing a grinding operation. After passing through the induced draft fan, the nitrogen is filtered and cooled down before entering the secondary air outlet of the grinder host, completing a cycle.

The whole process PLC strictly controls the oxygen content, and when the oxygen content exceeds the standard, nitrogen is automatically replenished to ensure the safety of the whole grinding system.

This system has a clear process route, compact system design, good stability, high efficiency and energy saving, easy operation and maintenance of equipment, less peripheral supporting equipment, reducing the scale of building construction, and has a high cost performance.

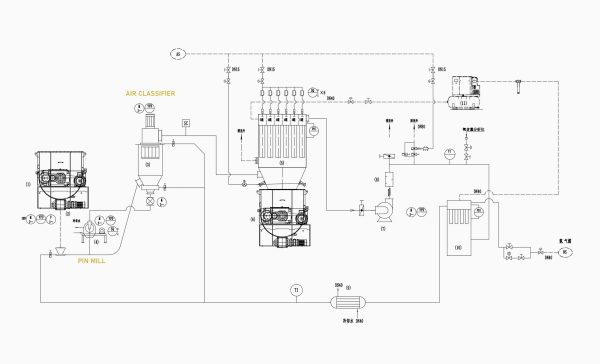

Process Flow Solution II

This option is applicable to the classifying of sulfur

This solution classifies sulfur powder, sieves the products that meet the particle size requirements and collects them. Oversize powder is output from the classifier’s lower discharge port and goes into the PIN MILL to be ground into fine powder and then returned to the classifier for sieving.

This process is also a nitrogen circulation process, the whole process PLC strictly control the oxygen content, after the oxygen content exceeds the standard, the nitrogen is automatically replenished to guarantee the safety of the whole grinding system.