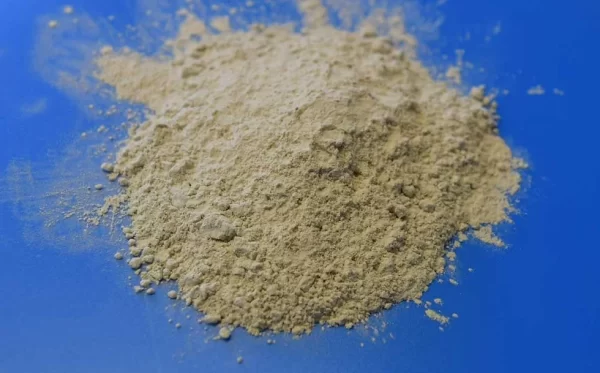

The morphology of sulfur blocks is orthorhombic. The cone surface of the crystal is well developed and occasionally appears as a thick plate. Common ones are in the form of fine lumps, stalactites, membranes, earthy shapes, etc. Colors include yellow, light yellow, light green yellow, grayish yellow, brown and black. The streaks are white to light yellow. The crystal mask has a diamond luster, and the fracture surface has a fat luster. translucent. The cleavage is incomplete and the fracture is shell-shaped or jagged. Hardness 1~2. The specific gravity is 2.05~2.08. Fragile. fragile. Hold it tightly with your hand and place it next to your ear, and you can hear a subtle popping sound. Light body. There is a peculiar odor. The taste is bland.

Temperature: The distance between the material temperature before granulation and the melting point or softening point of the sulfur block itself will directly affect the production capacity of the granulation device. The higher the temperature, the smaller the output value. The solution is to perform heat exchange treatment on the material before granulation, so as to give full play to the production capacity of the granulator.

Characteristics: The parameters that affect the granulation and molding of sulfur blocks mainly include melting point, specific gravity, heat transfer coefficient, specific heat, crystallization characteristics, viscosity and liquid surface tension, etc. Viscosity and surface tension mainly affect the molding quality of granulated products; other parameters mainly affect the cooling and solidification speed of the material, thereby affecting its output value; Viscosity and temperature: Generally, the viscosity of materials will decrease with the increase of temperature. However, the opposite is true when sulfur powder is granulated and molded. We need to pay corresponding attention.