Modern industry also has ultra-fine requirements for flammable, explosive and oxidizable materials in many fields, but these materials are prone to explosion when air is used as the medium for jet crushing. For example, when cobalt powder, sulfur and other materials were crushed with air as the medium, there were many explosion accidents, which brought huge losses and hidden safety hazards to processing enterprises. Therefore, for the fine processing of flammable, explosive and oxidizable materials, the need to achieve safety and explosion protection is the first problem that needs to be solved.

The explosion of combustible powder is caused by the instantaneous oxidation reaction of powder particles in contact with oxygen under specific conditions, which suddenly increases the volume, generates high temperature and releases gas. As we all know, combustible powder explosion requires combustible substances, oxygen and ignition source. Therefore, the explosion characteristics of combustible powder are related to powder concentration, powder particle size, oxygen concentration and ignition source.

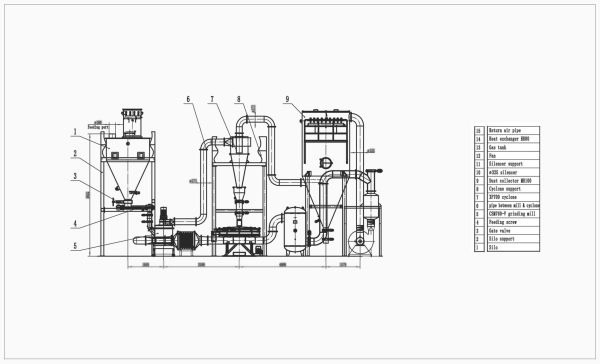

The inert gas protection airflow crushing system uses nitrogen, argon or other inert gases as the crushing medium. The system is under the protection of inert gas during the whole process of feeding, crushing, grading, conveying, separating and packaging. In the fully enclosed micro-positive pressure system, the oxygen content is controlled within the safety standard through the online detection of the oxygen analyzer and the automatic oxygen supply device, and the oxygen content in the mixture of dust and inert gas will be reduced to a value where the flame cannot spread; the oxygen content Reducing the ignition temperature, ignition energy and explosion lower limit of the dust cloud will increase at the same time, so that the ignition temperature and ignition ability of the dust cloud will decrease. When the volume fraction of oxygen is lower than a certain limit value, no matter how high the dust concentration is, the dust cloud cannot explode. This value is called the limit oxygen content of this kind of dust.

Performance advantages of inert gas protection airflow pulverization classification system

(1) Strong applicability: According to the properties of flammable, explosive and oxidizable materials, an inert gas suitable for it can be selected as the grinding medium.

(2) Wide crushing range: the particle size can be selected arbitrarily in the range of D97=2-15 microns.

(3) The product is pollution-free: when inert gas is used to crush flammable and explosive powders with supersonic airflow, the material particles are impacted by supersonic airflow and the particles collide with each other, collide and crush, and the product has high purity.

(4) The oxygen content in the system can be effectively controlled: In the system, the purity of the inert gas can be controlled according to the requirements of product characteristics, and the oxygen content can be set arbitrarily. Therefore, in the fully enclosed micro-positive pressure system, the oxygen content can be automatically controlled within the safety standard range; if the oxygen content does not reach the standard within the predetermined time, it will automatically shut down in an emergency. In addition, the inert gas can be recycled with minimal consumption.

(5) Control the concentration of the system without dust overflow: Since the material crushing system operates in a closed system, and the feeding system is also a fully enclosed and uniform-speed feeding device, the feeding speed is automatically adjusted with the change of the system concentration, and the equipment and pipelines are protected. Blocking structure, effectively reducing powder accumulation and dust overflow.

(6) Eliminate system static electricity and good explosion-proof performance: In view of the fact that the equipment and pipelines in the system are metal components, the dust collector uses conductive filter bags, and the whole system is well grounded to release powder static electricity as much as possible. The whole system adopts explosion-proof motors, electrical appliances and explosion-proof structures to ensure safe operation.

(7) High degree of automation: Advanced automation control is adopted in the system, so that the operating status can be displayed in real time, fully automatic control can be realized, and remote monitoring can also be realized.

Safety explosion-proof inert gas protection jet mill is widely used in chemical industry, pharmaceuticals, powder metallurgy, non-ferrous metals, chemical dangerous goods, and ultra-fine grinding of materials prone to static electricity.